The Sisyphus path-file format consists of a text file, containing an ordered list of 2-axis vertices, with each line containing the polar coordinates of a point on the unit circle. Algorithmic tools for composing paths are under development. Routines for converting standard vector file formats (AI and DXF) will be freely downloadable.

SISYPHUS TABLES CODE

NodeJS code on the RPi will be freely upgradable, as it evolves.

SISYPHUS TABLES SOFTWARE

Software overview – At the lowest level, the SBB runs a custom version of the EBB firmware, and conforms to the EBB command syntax. A single AC power cord plugs in to a standard outlet (total power consumption <100W for smaller tables, <200W for 4-foot table). Power is provided by a 12VDC supply for both the LED’s and Sisbot. Software dimmable white LED lighting surrounds the sandfield.

SISYPHUS TABLES SERIAL

Point-to-point commands are streamed from the Pi to the SBB over serial USB, and the SBB does the low-level timed generation of step / direction signals that govern the motors. Low-level motion control is handled by the SisBotBoard (SBB), designed by embedded systems engineer Brian Schmalz (designer of the EiBotBoard (EBB) for Eggbot). This includes both high-level motion control routines, file handling, and serving a two-way WiFi interface.

Hi level control is done by using code written in NodeJS, running on a Raspberry Pi 3.

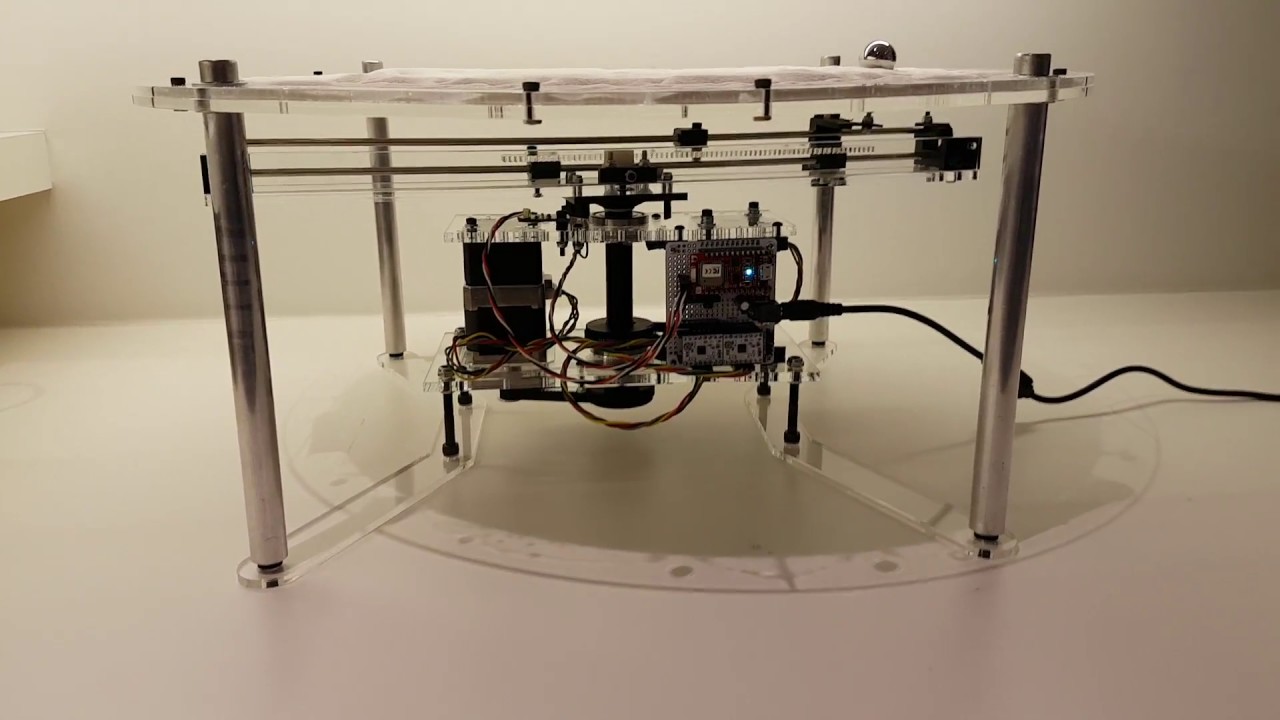

Brushless servomotors / drives are used for larger versions. The smaller versions (for sand fields < 40″ diameter) are stepper-actuated, using Trinamic drivers. Hardware overview – All Sisbots are two axis, polar plotters. The Sisbot demo unit How it works (Technical Details) And Micah, who keeps NEM humming, has joined my wife and me on the Sisyphus project team. Now three years old, NEM is thriving, and will serve as the center of production for Sisyphus. Six members, including Micah and myself, set off and started our own – Nordeast Makers. And it was there that I met Micah Roth– a tall, lanky, quiet dude, with a wry smile – who could make, fix, and figure out just about anything he set his mind to. It was there that I learned to value the cross-pollination of ideas that happens in makerspaces. It was there that I first got to use truly reliable CNC tools, spending my time making instead of fixing. I was building DIY CNC machines well before Make Magazine first published in 2005, but it was my time at a new makerspace in Minneapolis six years ago that made it possible to push further than I could ever have gone on my own. I owe a great deal to the Maker Movement for helping along the way. And so I’ve spent the last three years perfecting a home version that is beautiful, user-friendly, and that is near-silent and will run for years. It was also unique in another way – I wanted to live with it in my home. No longer tasked with cutting materials to be used in making sculpture, it was the sculpture itself. But of all works I made, Sisyphus stood out – it was my first CNC machine to break out of the studio/shop. In 1995, I registered my website: “ The Art of Motion Control.” My friends and family thought I was crazy (and I was) but my wife Beverly supported me, and I went on to create widely varied pieces involving metal, flying silk ribbons, and even bubbles. Where the companies had seen tools for mass producing floppy disks and sticky notes, I saw a new artistic medium. I discovered that industrial giants like 3M and Honeywell sold their used industrial equipment cheaply on the local surplus market, allowing me access to uber-expensive automation components at pennies on the dollar. 25 years ago I quit my job as a doctor to follow my passion: using computer-controlled machines to create art. This table is made with 70x70cm base, but you can make any size you want.My journey as an artist began, appropriately enough, with an egg ( Eggbot). I made sisyphus table, using some 20x20 extrusions,

0 kommentar(er)

0 kommentar(er)